Precision welding relies on equipment that performs flawlessly every time. Be it joining fine aluminium edges or tackling stainless steel assemblies, the outcome is only as good as your machine’s condition. Even with careful upkeep, components eventually wear down, affecting weld quality and consistency.

That is why knowing the early warning signs of a struggling TIG welder is so important. Small changes in performance can often reveal much about what is wrong with your welder. Spotting those clues early not only prevents costly breakdowns but also keeps your workflow smooth and your welds looking as clean as they should.

Inconsistent Arc Performance and What It Tells You

Few things are as telling as an unpredictable arc. If it flickers, flares, or struggles to start cleanly, the issue might run deeper than a dirty tungsten or a loose ground clamp. These irregularities often suggest that internal components such as capacitors or power boards are beginning to deteriorate. Capacitors, for example, store and release energy to maintain a stable arc; when they age, they cause voltage fluctuations that manifest as arc instability.

It is always worth addressing the simple fixes first. But if stability isn’t restored, don’t push through the problem. An erratic arc stresses the machine and can hasten further damage.

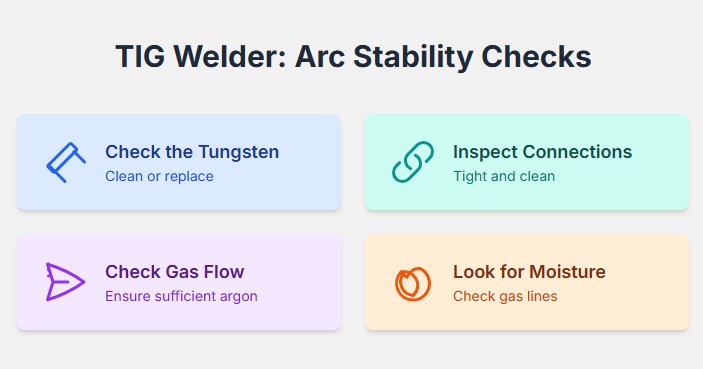

Before calling a technician, check these common culprits:

- Check the Tungsten: Clean or replace your tungsten.

- Inspect Connections: Ensure the ground clamp and torch connections are tight and clean.

- Check Gas Flow: An insufficient argon flow can mimic arc issues by allowing atmospheric contamination.

- Look for Moisture: In humid environments, moisture can build up in gas lines and cause porosity.

Noises, Overheating, and Other Warning Clues

TIG welders generally operate with a smooth hum, so any unusual buzzing, rattling, or grinding is a red flag. Such noises can stem from worn bearings, loose components, or even an issue with the cooling fan.

Heat is another clue that should not be ignored. If your welder begins running noticeably hotter than usual, particularly in areas that typically stay cool, it could point to a cooling system fault. Overheating can quickly lead to damage inside the power module, sometimes beyond repair. A persistent hot smell or unfamiliar odour during use is your cue to switch off and call for a check-up.

Poor Weld Appearance and Increased Spatter

TIG welding is prized for its crisp, clean finishes. So when you start noticing extra spatter, uneven beads, or tiny cracks appearing where they shouldn’t, you need to have a deeper look. While technique and settings play a role, persistent flaws often trace back to the machine itself.

Problems like a failing high-frequency start unit or contamination in the shielding gas line can be difficult to spot but have a huge impact on the finished weld. Catching these mechanical or electrical faults early helps prevent small imperfections from becoming bigger structural issues.

Faulty Displays and Unresponsive Controls

Modern machines have made life easier with digital readouts and fine-tuned control panels, but when those start acting up, it is time to pay attention. If your display flashes error codes, freezes, or your buttons become temperamental, chances are the control board is on its way out.

At first, it might just seem like an inconvenience. Yet with time, these electronic problems can lead to inaccurate outputs, making it impossible to trust your settings. Once that happens, consistency goes out the window. A technician can run diagnostics and replace faulty circuits before they affect your workflow.

Staying Ahead with Regular Maintenance

Even when everything seems fine, components can slowly degrade behind the scenes. Routine checks typically involve cleaning out dust and metal debris, inspecting fans and filters, and verifying that electrical outputs remain within spec.

Following the manufacturer’s maintenance guidelines is always a smart move in busy or harsh work environments. And if your machine starts showing any of the symptoms above, don’t delay a professional inspection. Servicing at the right time often costs far less than waiting until something fails completely.

Final Thoughts

The more familiar you become with your equipment, the easier it is to spot when something is not quite right. Whether it is a flickering arc, unexpected heat, or a glitching display, every signal matters. Staying proactive about maintenance ensures that your welder performs consistently, keeps your projects on schedule, and extends the life of your investment.