The construction industry has come a long way from relying solely on bricks, mortar, and manual processes. As technology continues to evolve, so do the materials and methods used to shape modern infrastructure. One of the most underrated, yet impactful advancements in recent years has been the integration of thermoplastic materials into site design, especially when it comes to line marking, safety, and long-term durability.

Whether it’s a large commercial development, a housing estate, or an industrial facility, clearly defined layouts and visible markings have become essential for efficiency and safety. And that’s exactly where thermoplastics are making their mark.

The Rise of Smarter Surface Solutions

Thermoplastic markings are increasingly being seen not just as road-related tools but as core components of modern construction site planning. Professional road marking contractors now rely on these materials to create accurate, highly visible lines and symbols that guide both vehicles and workers safely across active sites. Their strength and flexibility allow them to withstand extreme weather, heavy traffic, and continuous wear, making them ideal for long-term use during and after construction.

Contractors and site managers are turning to thermoplastic rolls and symbols for quick, reliable, and professional line marking that doesn’t require complex equipment or extended drying times. The result is a fast, cost-effective way to improve visibility and safety on active sites, something that traditional paint simply can’t match.

Enhancing Safety and Workflow Efficiency

On any construction site, time is money, but so is safety. The use of thermoplastic markings to designate pedestrian walkways, heavy-machinery zones, and vehicle pathways has been proven to reduce on-site accidents and confusion.

Unlike paint, which can fade within months under harsh conditions, thermoplastic materials retain their brightness and definition for years. This long lifespan not only reduces maintenance costs but also ensures that high-traffic zones remain clearly marked, even after months of wear.

For project managers, this means fewer interruptions, smoother traffic flow, and a lower risk of workplace injuries, all while maintaining compliance with safety standards.

A Sustainable Approach to Modern Construction

Sustainability has become one of the defining goals of modern architecture and infrastructure. Interestingly, thermoplastic technology aligns perfectly with this mission.

Thermoplastics are made to last, meaning fewer reapplications and less waste. Their durability translates to a smaller carbon footprint over time, as contractors need to use fewer resources and less energy to maintain site markings. Many modern formulations are even developed with eco-friendly compounds, ensuring compliance with environmental regulations.

For developers focused on sustainable design, that’s an easy win combining efficiency, longevity, and lower lifecycle costs.

Design Meets Functionality

While the functional benefits are clear, thermoplastic markings are also being recognized for their aesthetic potential. Construction sites are evolving into more organized, design-driven spaces even before the final structure takes shape.

Brightly colored lines and symbols bring a level of order and clarity that complements the overall design vision. Beyond safety, they help communicate professionalism and precision, two traits that clients increasingly value in today’s construction landscape.

This combination of durability, safety, and style has positioned thermoplastic rolls and symbols as an indispensable part of modern construction workflows.

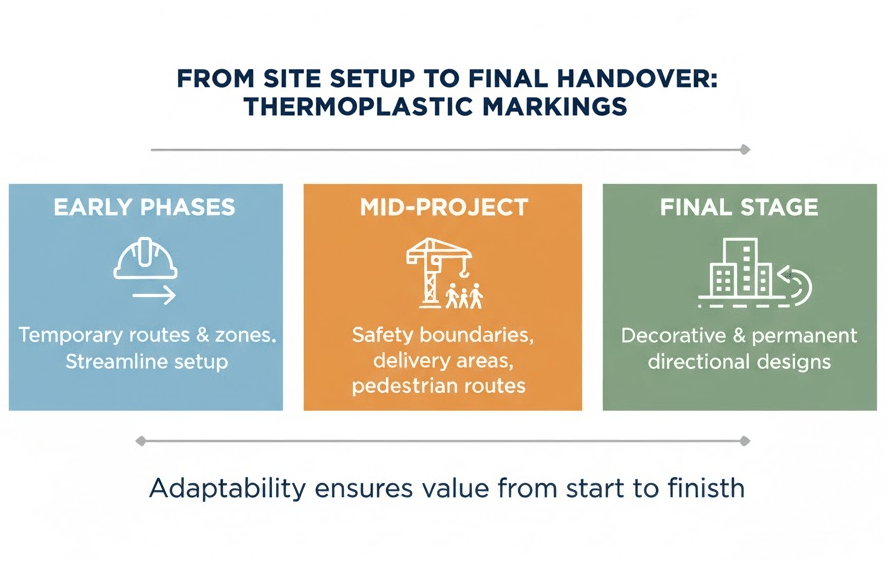

From Site Setup to Final Handover

One of the biggest advantages of thermoplastic markings is their versatility across project stages.

- Early phases: Mark out temporary routes and zones to streamline setup and logistics.

- Mid-project: Reinforce safety boundaries, delivery areas, and pedestrian routes as the site becomes busier.

- Final stage: Use decorative markings or permanent directional designs that remain as part of the completed facility.

This adaptability ensures that thermoplastics serve a purpose from start to finish, adding value beyond initial installation.

Drawbacks & Limitations

Thermoplastic materials bring many advantages, but they also have limitations project teams should consider. First, thermoplastics typically have a higher upfront cost and require specialized application equipment and trained crews, making them less cost-effective for very small or short-term markings.

Removal and rework can be more challenging: thermoplastic is designed to bond strongly to surfaces and can be harder to remove than paint if the area later requires resurfacing or redesign. In hot climates or during application errors, the material can be sensitive to improper heating, and stray heat sources post-installation (e.g., welding torches) can damage markings. Snowplow and heavy abrasion zones also reduce lifespan in some situations, so local conditions must be evaluated.

Future Trends & Innovations

- Eco-formulations & recycling: Suppliers are developing bio-based resins, low-VOC blends, and processes for recovering thermoplastic materials from overlays. Research into economically viable recycling and recovery methods is maturing.

- Higher-performance reflectivity: Wet-reflective additives and optimized glass bead technology improve night and wet-weather visibility. Standards and testing continue to evolve to measure these factors more rigorously

- Smart and photoluminescent markings: Trials are underway to integrate photoluminescent pigments or embedded sensors in markings for temporary guidance, low-light performance, and even vehicle-to-infrastructure signaling in future smart sites.

- Hybrid materials & alternate chemistries: Cold-applied MMA and other polymer systems compete with traditional thermoplastics for niche cases (e.g., cold environments, thin applications), and ongoing material innovation aims to balance safety, durability and ease of application.

The Bottom Line

Thermoplastic rolls and symbols remain a practical, long-lasting, and increasingly eco-aware choice for construction site line marking and design when used in the right contexts. By acknowledging limitations, following proven standards, and applying sound site management practices, contractors can use thermoplastics to enhance both safety and operational efficiency across every project phase.

When integrated thoughtfully into broader construction management strategies, thermoplastics deliver measurable improvements in visibility, sustainability, and workflow coordination—setting a higher standard for modern, data-informed site operations.